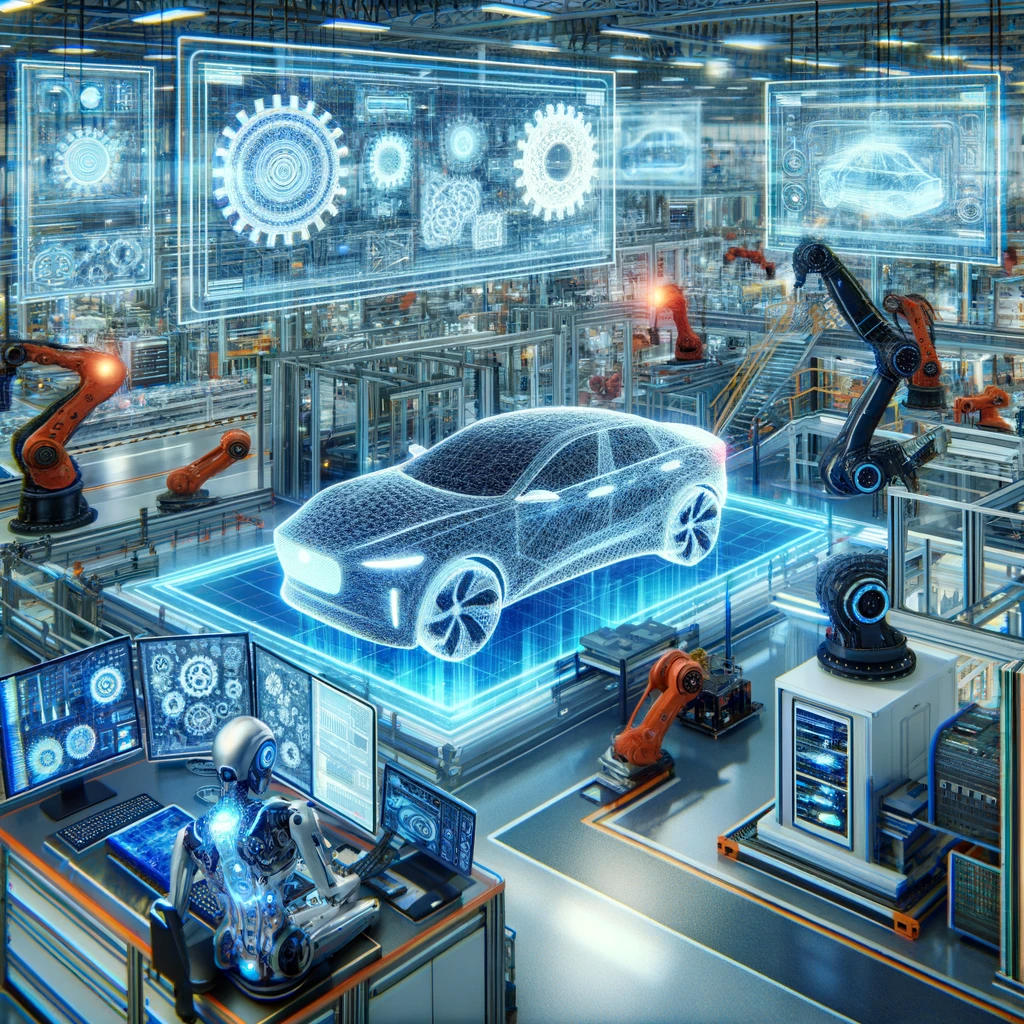

The incorporation of Generative AI into manufacturing represents a significant evolution from traditional machine learning techniques. Its advanced capabilities in processing complex data and generating new content provide...

Unlocking the Potential of High-Res Data: Transforming Manufacturing with Predictive Maintenance, Quality Control, Forecasting, and Anomaly Detection.

Manufacturing is a complex and dynamic industry that requires real-time data to achieve maximum efficiency and productivity. High-resolution data collection is a critical component of modern manufacturing, offering manufacturers the ability to collect and analyze data from all kinds of sources, including machines, sensors, and devices.

With the advancements in technology, collecting high-res data has become more accessible and affordable than ever before. The rise of Industry 4.0, IoT, and cloud technology has made it possible to collect Terabytes of data from all corners of the manufacturing process, and store it in the cloud for safekeeping and analysis.

But what can you do with all this data? The answer lies in predictive maintenance, quality control, demand forecasting, and anomaly detection.

Predictive Maintenance is a process that uses data to predict when a machine is likely to fail, allowing manufacturers to schedule maintenance in advance, preventing downtime, and reducing the risk of costly repairs. Predictive Quality enables manufacturers to identify quality issues in real-time, allowing them to make changes to production processes before the quality problems become critical.

Demand forecasting is the process of using historical data to predict future demand for products. By analyzing this data, manufacturers can optimize production processes, reduce waste, and improve the accuracy of their forecasts. Anomaly detection is the process of identifying unusual or unexpected behavior in production data, allowing manufacturers to identify and resolve problems before they become critical.

Storing data in the cloud makes it possible to use "off-the-shelf" vertical solutions that can be tailored to specific needs. These solutions can be easily integrated with existing systems, providing manufacturers with the latest technologies without the need for expensive infrastructure. The cloud also provides a secure and scalable platform for data storage, ensuring that data is safe and secure.

One concrete example of Predictive Quality shows a medium size process manufacturer that was able to predict 70% of the rejects 3 hours on average ahead of time and reduce waste by nearly 30% by using high-resolution data collection and "off-the-shelf" predictive maintenance techniques. This case highlights the importance of high-resolution data collection and the benefits it can bring to the manufacturing industry.

In conclusion, high-resolution data collection is a game changer for the manufacturing industry. With the ability to collect and analyze data from all sources, manufacturers can achieve predictive maintenance, quality control, demand forecasting, and anomaly detection, leading to increased efficiency, reduced waste, and improved productivity. So why wait? Unlock the potential of high-res data today and transform your manufacturing process!

From our blog

Automation, DROPS, AI, IOT

Manufacturing DROPS: Quantifying Data-Related Operational Losses with IoT, High-Resolution Data Collection, and AI

In the manufacturing industry, operational efficiency is crucial for maintaining competitiveness. Companies have long relied on LEAN manufacturing principles to minimize waste and maximize productivity. However, rapid...